Moreover, a 2019 study noted that food-grade titanium dioxide was larger and not nanoparticles. Hence, the authors concluded that any titanium dioxide in food is absorbed poorly, posing no risk to human health (3Trusted Source).

Currently, the development of TiO2 memristors is associated with their use in modern highly technological applications, such as resistive random-access memory (RRAM), biohybrid systems, and sensors, as schematically shown in Figure 1A. In this mini-review, we briefly outline and summarize the key milestone achievements, as well as recent advances in the synthesis, fabrication, and application of TiO2-based memristors. A special focus is placed on the relationships between the synthesis and deposition methods, the effects of post-synthesis treatment, and the resistive switching properties.

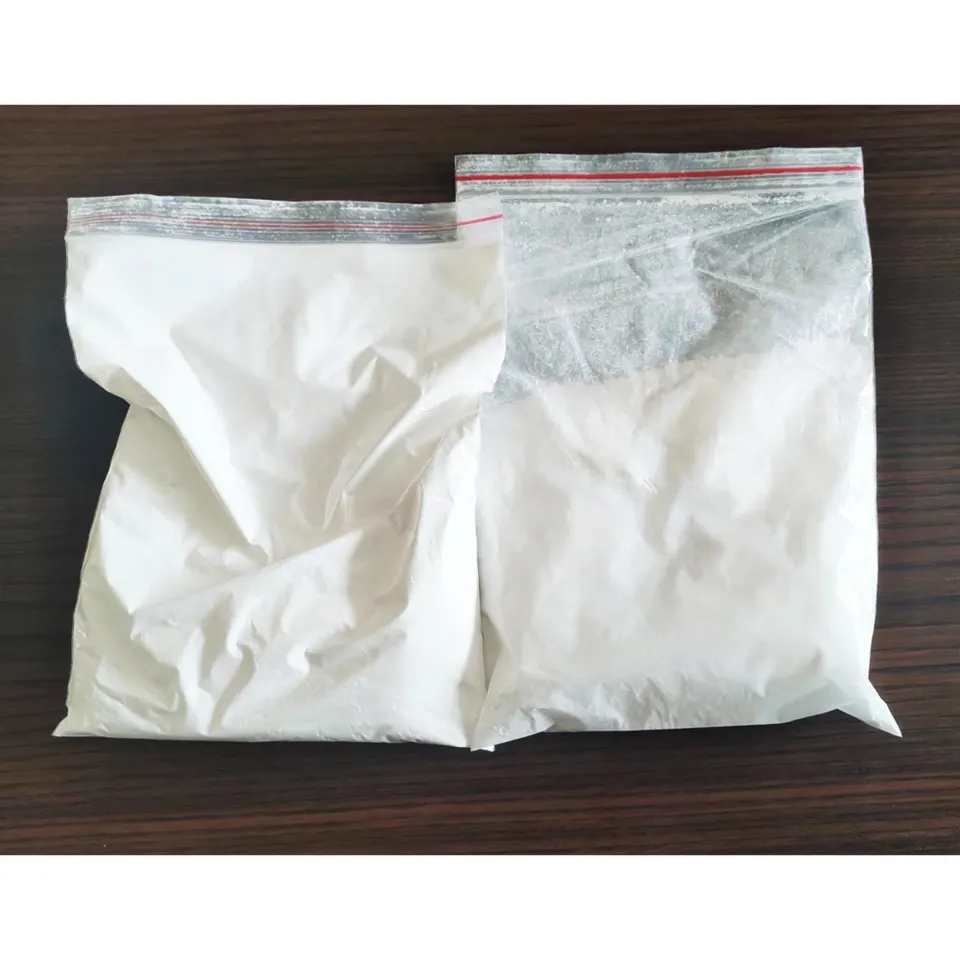

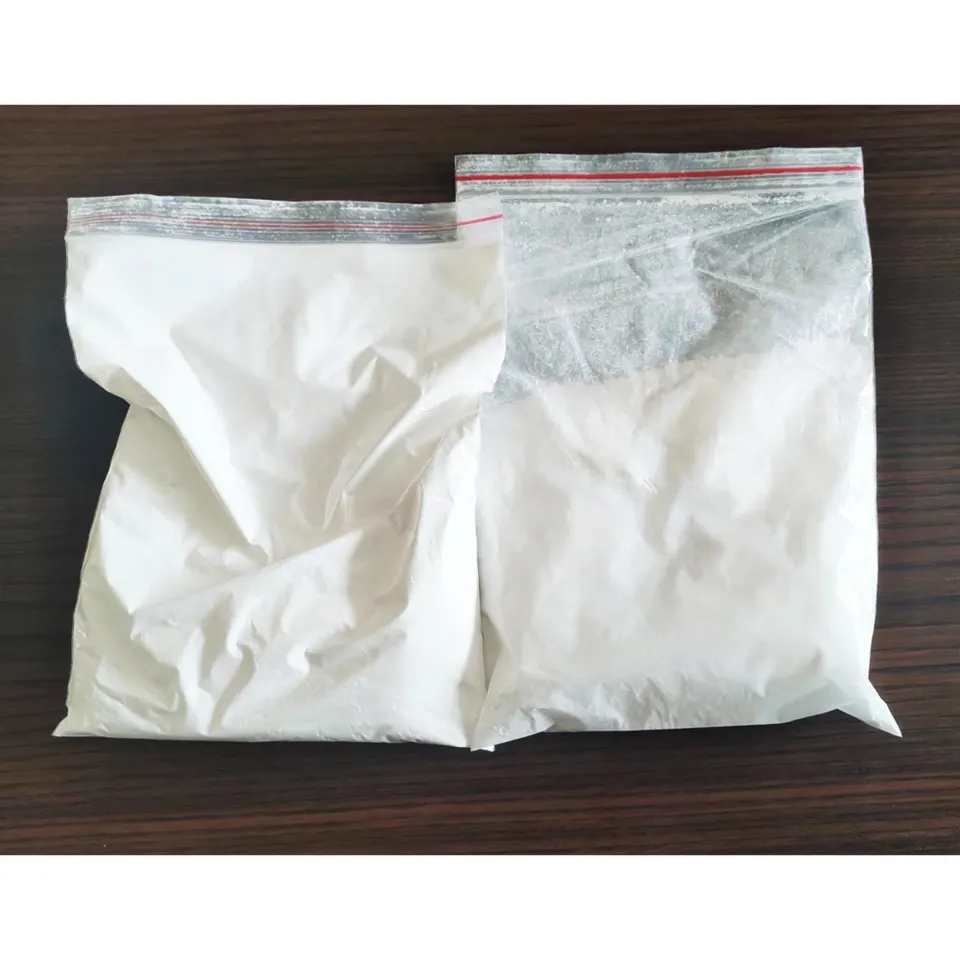

Titanium dioxide A1 adopts good oxidation process, composite inorganic coating and organic treatment, and has the characteristics of excellent particle size distribution, high brightness and high weather resistance. It is recommended for high gloss and high weather resistance coatings, inks and outdoor polymer materials.

Micronized titanium dioxide doesn’t penetrate skin so there’s no need to be concerned about it getting into your body. Even when titanium dioxide nanoparticles are used, the molecular size of the substance used to coat the nanoparticles is large enough to prevent them from penetrating beyond the uppermost layers of skin. This means you’re getting the sun protection titanium dioxide provides with no risk of it causing harm to skin or your body. The coating process improves application, enhances sun protection, and prevents the titanium dioxide from interacting with other ingredients in the presence of sunlight, thus enhancing its stability. It not only makes this ingredient much more pleasant to use for sunscreen, but also improves efficacy and eliminates safety concerns. Common examples of ingredients used to coat titanium dioxide are alumina, dimethicone, silica, and trimethoxy capryl silane.

After conducting a review of all the relevant available scientific evidence, EFSA concluded that a concern for genotoxicity of TiO2 particles cannot be ruled out. Based on this concern, EFSA’s experts no longer consider titanium dioxide safe when used as a food additive. This means that an Acceptable Daily Intake (ADI ) cannot be established for E171.

The Market Dynamics of Wholesale Titanium Dioxide

Health Canada's Food Directorate recently completed a “state of the science” report on titanium dioxide (TiO2) as a food additive. Food-grade TiO2 is a white powder made up of small particles that has been permitted in Canada and internationally for many years as a food additive to whiten or brighten foods. Food-grade TiO2 has long been considered safe in Canada and in other countries when eaten as part of the diet.

The most common foods containing titanium dioxide are chewing gum, candies, pastries, chocolates, coffee creamers, and cake decorations (1Trusted Source, 3Trusted Source).

products with titanium dioxide manufacturers. Manufacturers must employ state-of-the-art technology and equipment to ensure that their products are produced efficiently and effectively. Additionally, manufacturers must also consider the environmental impact of their production processes and strive to minimize their carbon footprint.

Titanium dioxide (TiO2) is a versatile compound widely utilized in various industries, particularly in the production of paints, coatings, plastics, and paper. The accurate determination of titanium dioxide content is essential for quality control purposes in these manufacturing processes. Among the various methods available for quantifying TiO2, gravimetric analysis stands out due to its reliability and accuracy. This article explores the gravimetric determination of titanium dioxide, its significance in factory settings, and the technical processes involved.

Following the filtration, the precipitate is washed thoroughly to remove any impurities and excess reagents. This is a crucial step, as thorough washing ensures that no contaminants interfere with the final mass measurement. Once washed, the precipitate is dried in an oven at a controlled temperature to remove moisture, ensuring that the mass recorded reflects only the titanium content.

gravimetric titanium dioxide determination factory

This not only prolongs the lifespan of the product but also protects it from fading and discoloration over time This not only prolongs the lifespan of the product but also protects it from fading and discoloration over time

This not only prolongs the lifespan of the product but also protects it from fading and discoloration over time This not only prolongs the lifespan of the product but also protects it from fading and discoloration over time titanium dioxide for plastic manufacturer.

titanium dioxide for plastic manufacturer. They help to strengthen the body's defenses against infection and disease by supporting the production of white blood cells They help to strengthen the body's defenses against infection and disease by supporting the production of white blood cells

They help to strengthen the body's defenses against infection and disease by supporting the production of white blood cells They help to strengthen the body's defenses against infection and disease by supporting the production of white blood cells antioxidant. This makes them an essential part of any healthy diet or supplement regimen.

antioxidant. This makes them an essential part of any healthy diet or supplement regimen.Titanium Dioxide Manufacturer Rutile Titanium Dioxide R996 Industrial Grade Lomon Billions TiO2 R996